- (800) 334-0135 or (541) 471-0194

- info@ronellclock.com

- Mon - Thur: 9am-4pm & Fri 9am-12pm (Pacific Time)

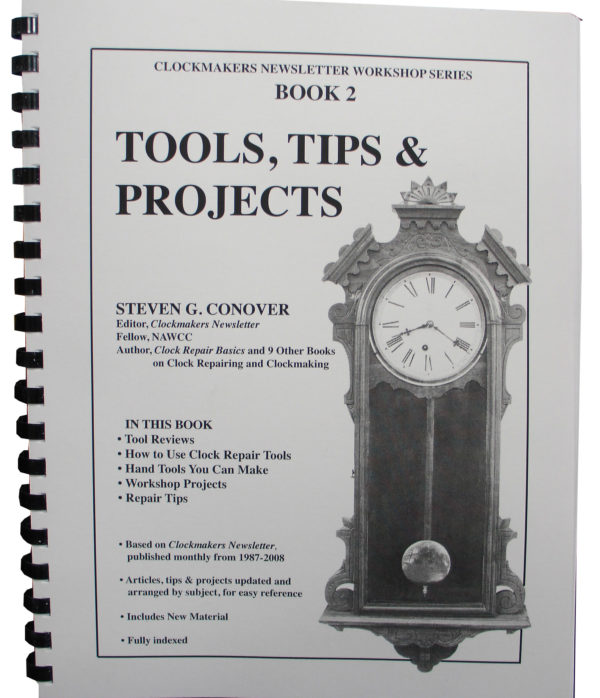

Book 2: Tools, Tips & Projects in Workshop series by S. Conover

This book presents a subject that catches the interest of clock repair enthusiasts right away: tools! Specialized tools for the beginner to advanced repairman. Chapter 1, “Making Tools”, describes how to make the accessories and tools that will make your clock repair work more efficient and enjoyable. Examples include modifications to your lathe, bushing tool, and mainspring winder. In addition, you’ll find instructions for making a trundle cutter, a split stake, and various small tools such as a gathering pallet stake, assembly clamps, and pivot burnishers. Chapter 2, “Using Tools”, presents information on selecting and using specialized clock repair tools. There are product reviews of a bushing tool, a movement holder, seven clock timers, gear cutting attachments, and more. There are also five articles from a “Tools for the Clock Shop” series by Michael Ambrosino, MBHI. Chapter 3, “Projects”, will give you plenty of ideas on how to improve your workshop. There are 14 test stands you can make for running grandfather, cuckoo, OG, and other clock movements! You’ll also find other projects such as a broach stand, a clock parts dryer, and tips such as making small washers and machining a custom designed dial grommet. Chapter 4, “Repair Tips” is a gold mine of ideas from the popular Clockmakers Newsletter feature. Examples include duplicating seatboard screws, making replacement American-style click springs, safely removing gathering pallets, making threaded pillar extensions to ease movement reassembly, and punching perfect holes in suspension spring steel.

This book has 181 pages featuring 293 photos and drawings with introduction, table of contents, and index. It is comb bound like Steven G. Conover’s other workshop manuals, allowing it to open flat on your bench for easy reference. 9×11″. Soft Cover.

Availability: 1 in stock

$37.95

This book presents a subject that catches the interest of clock repair enthusiasts right away: tools! Specialized tools for the beginner to advanced repairman. Chapter 1, “Making Tools”, describes how to make the accessories and tools that will make your clock repair work more efficient and enjoyable. Examples include modifications to your lathe, bushing tool, and mainspring winder. In addition, you’ll find instructions for making a trundle cutter, a split stake, and various small tools such as a gathering pallet stake, assembly clamps, and pivot burnishers. Chapter 2, “Using Tools”, presents information on selecting and using specialized clock repair tools. There are product reviews of a bushing tool, a movement holder, seven clock timers, gear cutting attachments, and more. There are also five articles from a “Tools for the Clock Shop” series by Michael Ambrosino, MBHI. Chapter 3, “Projects”, will give you plenty of ideas on how to improve your workshop. There are 14 test stands you can make for running grandfather, cuckoo, OG, and other clock movements! You’ll also find other projects such as a broach stand, a clock parts dryer, and tips such as making small washers and machining a custom designed dial grommet. Chapter 4, “Repair Tips” is a gold mine of ideas from the popular Clockmakers Newsletter feature. Examples include duplicating seatboard screws, making replacement American-style click springs, safely removing gathering pallets, making threaded pillar extensions to ease movement reassembly, and punching perfect holes in suspension spring steel.

This book has 181 pages featuring 293 photos and drawings with introduction, table of contents, and index. It is comb bound like Steven G. Conover’s other workshop manuals, allowing it to open flat on your bench for easy reference. 9×11″. Soft Cover.